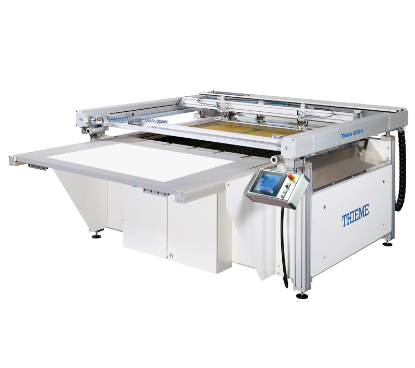

Ημιαυτόματο επίπεδο μηχάνημα μεταξοτυπίας με μορφή «αχιβάδας», για πολλές εφαρμογές

Thieme 500

Ημιαυτόματο επίπεδο μηχάνημα μεταξοτυπίας με μορφή «αχιβάδας», κατάλληλο για πλήθος εφαρμογών.

Βασική κατασκευή μηχανήματος

Ατσάλινος σκελετός, ανθεκτικός στη στρέβλωση

- Εκτεθειμένες επιφάνειες ή εξωτερικά μέρη επικαλυμμένα είτε με χρώμα ανθεκτικό σε διαλύτες είτε με φινίρισμα μεγάλης διάρκειας ζωής

- Πλευρική επένδυση που απορροφά το θόρυβο για χαμηλότερα επίπεδα ήχου (περίπου 74 DbA)

Τραπέζι εκτύπωσης

Κατασκευή από τριπλή στρώση αλουμινίου με ανοδιωμένες επιφάνειες

- Ελεύθερη τοποθέτηση της επιφάνειας υποδοχής

- Τρύπες διαμέτρου 1,5 χιλ. στο τραπέζι εκτύπωσης σε απόσταση 15 χιλ. μεταξύ τους

- Ύψος τραπεζιού εκτύπωσης για ρύθμιση από απόσταση από 0 - 40 χιλ. μέσω κεντρικού στροφάλου χειρός

- Διαβαθμισμένη μικρορύθμιση +/- 10 χιλ. σε 3 άξονες

Σπάτουλα εκτύπωσης

Υδραυλική μεταβολή ή αντιστροφή από τη σπάτουλα εκτύπωσης στη σπάτουλα επάλειψης, και αντίστροφα για κάθε πέρασμα

- Υδραυλικός έλεγχος της πίεσης της σπάτουλας εκτύπωσης, με αυτόματη ρύθμιση παράλληλης θέσης με την κλίση του τραπεζιού εκτύπωσης

- Απεριόριστη ρύθμιση της γωνίας της σπάτουλας εκτύπωσης και της σπάτουλας επάλειψης, ανεξάρτητα από την μπάρα στήριξης του φορέα της σπάτουλας εκτύπωσης

- Σφιγκτήρες που απελευθερώνουν εύκολα τη σπάτουλα εκτύπωσης και τη σπάτουλα επάλειψης για άμεση εισαγωγή ή αφαίρεση

- Ένα σετ σπάτουλας εκτύπωσης και σπάτουλας επάλειψης μέγιστου μήκους ανάλογα με το μέγεθος του μηχανήματος

Έλεγχος της σπάτουλας

Ο έλεγχος της σπάτουλας εκτύπωσης επιτυγχάνεται από ένα τριφασικό μοτέρ ταχυτήτων, ελεγχόμενης συχνότητας και με ρυθμιζόμενο ποτενσιόμετρο, και έναν οδοντωτό ιμάντα κίνησης

- Οι ταχύτητες της σπάτουλας εκτύπωσης και της σπάτουλας επάλειψης ρυθμίζονται απεριόριστα και ανεξάρτητα

- Το μήκος του περάσματος της σπάτουλας εκτύπωσης ρυθμίζεται απεριόριστα χρησιμοποιώντας διακόπτες ακριβείας

- Η ακριβής κίνηση του φορέα της σπάτουλας εκτύπωσης επιτυγχάνεται χρησιμοποιώντας κυλίνδρους μεταφοράς φορτίου από ανθεκτικό συνθετικό υλικό

Τοποθέτηση της κεφαλής εκτύπωσης και του τελάρου μεταξοτυπίας

Το άνοιγμα και κλείσιμο της κεφαλής εκτύπωσης ρυθμίζεται μηχανικά για ομαλή, χωρίς δυσκολίες κίνηση

- Η επιμήκυνση της θέσης καθαρισμού ελέγχεται από διακόπτη

- Η τοποθέτηση του τελάρου μεταξοτυπίας γίνεται με γρήγορη εισαγωγή από την μπροστινή πλευρά της μηχανής

- Οι μπάρες στήριξης του τελάρου μεταξοτυπίας μετακινούνται εύκολα για να δεχτούν διαφορετικά μεγέθη τελάρου

- Το τελάρο μεταξοτυπίας συγκρατείται στη θέση του μηχανικά

- Εξάρτημα τριών σημείων στήριξης του τελάρου

Σύστημα ανασήκωσης τελάρου

Το ύψος της ανασήκωσης του τελάρου ρυθμίζεται απεριόριστα από 0 έως 50 χιλ. ανά 200 χιλ. μήκους περάσματος ή ένα μέγιστο ποσοστό ανασήκωσης 2,5 χιλ./γραμμικό εκατ.

- Η γραμμή αναφοράς ή το σημείο εκκίνησης του συστήματος ανασήκωσης ρυθμίζεται απεριόριστα κατά πλάτος του μήκους περάσματος της σπάτουλας εκτύπωσης

- Η μηδενική κλίση της σπάτουλας επάλειψης επιτρέπει στο τελάρο μεταξοτυπίας να είναι παράλληλο με το τραπέζι εκτύπωσης κατά τη διάρκεια του περάσματος επάλειψης

Ταμπλώ ελέγχου

Εξοπλισμένο με έναν ρυθμιστή που προγραμματίζεται όπως επιθυμείτε

- Ένας διακόπτης τριών θέσεων ρυθμίζεται μεταξύ "Εγκατάστασης", "Κύκλου εκτύπωσης" ή "Αυτόματης" λειτουργίας

- Εκκίνηση του κύκλου από έναν διακόπτη-πεντάλ που ρυθμίζεται με το πόδι

- Εκκίνηση του κύκλου μέσω δύο διακοπτών σε σχήμα μανιταριού

- Το ταμπλώ ελέγχου είναι συνδεδεμένο με το εκτυπωτικό τμήμα της μηχανής

-

.png)