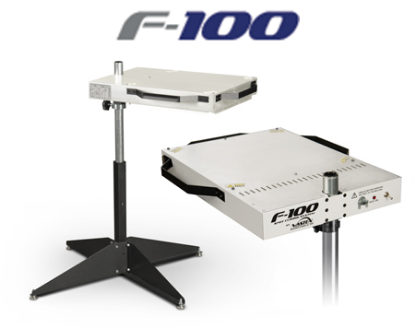

The multi-purpose LittleRed® X3-D infrared dryer cures direct-to-garment (DTG) printed textiles as well as plastisol, water-based and discharge-printed garments, and/or adhesive-coated DTF images, at higher rates than possible with conventional dryer designs. The modular design allows for expandability to easily add chambers and conveyor length as production needs increase.

Available in 76, 137, and 198 cm belt widths, it features a high-powered pre-heating zone that rockets ink temperatures past 149°C within the first several inches of conveyor travel, maximizing the distance and dwell time for optimum curing of any ink or adhesive, allowing increased conveyor belt speeds and dryer output.

The Little Red X3-D-30 model is equipped with a 76.2 cm wide conveyor belt and three 61 cm wide infrared heaters (8900W @ 240V total wattage) and can cure 360+ plastisol-printed garments/h, 185+ water-based or discharge-printed garments/h, and up to 51+ garments/h inkjet printed with digital white ink at 3 minutes dwell time.*

The 137 cm wide LittleRed X3-D-54 model cures 720+ plastisol-printed garments/h, 370+ water-based or discharge-printed garments/h, and 103+ garments/h inkjet printed with digital white ink or pretreated for DTG printing at 3 minutes dwell time.*

The 198 cm wide LittleRed X3-D-78 model accommodates up to three rows of garments, and cures a whopping 1080+ plastisol-printed garments/h, 555+ water-based or discharge-printed garments/h, and 155+ garments/h inkjet printed with digital white ink or pretreated for DTG printing at 3 minutes dwell time.*

The X3-D-30 and X3-D-54 models have an overall conveyor belt length of 224 cm long while the X3-D-78 model has an overall length of 260 cm. The heating chamber for all three models is 104 cm long and features a powerful, targeted exhaust system as standard to rapidly remove moisture and air contaminates from the heating chamber, as well as cool the skin and controls.

With a second X3 chamber, the LR-X3D-30-2 and LR-X3D-54-2 can handle higher production including longer times necessary for Kornit printers.

.png)