Textile

|

|

The textile market is growing, mainly due to the increasing e-commerce and a vast demand for garments in the fashion sector. Fashion is the largest application segment, owing to the fast-changing fashionable trends, followed by technical clothing (see smart textiles) and household textiles (bedding, upholstery, carpets, curtains e.t.c.).

For industrial textile production, no other printing process offers as many options as screen printing. Application and substrate variety, haptic, optical or olfactory effects, perfect coverage, high wash resistance, transfer and much more: screen printing can do it all.

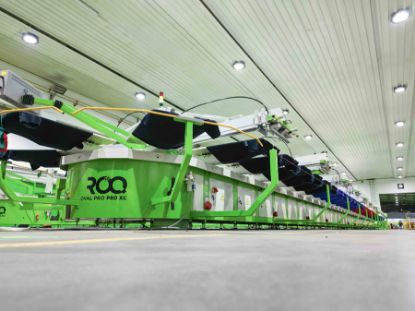

ROQ’s rich offering of screen printing and hybrid (screen-digital) machines for the fashion and promotional markets, combined with the appropriate drying and packaging equipment, are available by GRAPHCOM. THIEME’s printing solutions are suitable for transfers on t-shirts, polo shirts, caps, jackets, bags, functional clothing e.t.c. For small productions of garments and restricted spaces, VASTEX and ACOSGRAF manual presses offer 1 to 10 color printing, depending on the model and configuration.

SignTronic has designed a dedicated “TEX series” of CtS machines for upmarket textile printers. Natgraph’s drying and curing technology provides a productive solution for exceptional quality in textile transfer and labels applications. INKNOVATORS formulates next generation hybrid water based inks, water based polyurethane inks and plastisol inks to meet all textile printing demands.

Digital printing

Décor and fashion application trends, on demand production and personalization are boosting digital print growth. HP’s inkjet technologies provide unique versatility by allowing users to print direct-to-fabric and on transfer paper, for a wide range of applications in the areas of sportswear/fashion, interior décor and soft signage. HP Stitch dye sublimation printers deliver fast, precise color-matching and printer-to-printer color consistency alongside efficient, simplified processes. Ideal for printing on polyester and stretchable fabrics, they ensure superior color durability, resistance to laundering and vivid colors on both sides of the printed fabric.

HP Latex water-based systems print on coated and uncoated textiles made from cotton, polyester or natural fiber blends. Prints are odorless, certified for indoor use, suitable for home décor, soft signage or promo apparel applications.

For t-shirts and garment customization capabilities, ROQ’s digital and hybrid DTG (Direct-to-Garment) systems, combined with the appropriate pre-treating equipment, are ideal for web-to-print workflows.

Finishing equipment

When it comes to speed and accuracy in polyester sportswear and soft signage finishing, laser cutters are the perfect solution. Summa L series feature advanced OptiPower technology for high precision contactless cutting, optimum productivity, unique camera technology with various cutting options - even without the need for registration marks or a cutting file - and high automation levels. Definitely the technology of choice for dye sublimation prints, sportswear, fashion, technical clothing, soft signage and interior decor applications!

For thick substrates, such as banners and other thick soft signage media, Summa F Series flatbed knife cutters are more suitable - they can also process perfectly pieces of cotton, denim, and other thicker natural fibres.

Summa has also engineered a vinyl cutter specifically for DTF (Direct-to-Film) applications. This special version of the S3 TC75 cutter is equipped with a frictionless roll feed, a roll-up system and the advanced GoSign Pro Pack software.

Check out also our GRX Green heat transfer calenders for dye sublimation transfers on roll-to-roll and piece productions.

.png)