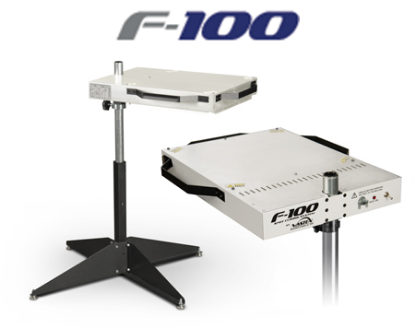

Ιδανικά για μεσαία-μεγάλη παραγωγκή δυνατότητα σε DTG και μεταξοτυπία.

Τα υπερ-παραγωγικά μοντέλα Little Red X3D στεγνώνει υφάσματα εκτυπωμένα με DTG, καθώς και υφάσματα τυπωμένα με μελάνια plastisol, νερού ή ξεβαφής καθώς και κόλλα για DTF, σε υψηλότερους ρυθμούς από ό,τι είναι δυνατό με συμβατικούς φούρνους. Ο αρθρωτός σχεδιασμός επιτρέπει την εύκολη επέκταση με πρόσθετους θαλάμους και επιμήκυνση του ιμάντα μεταφοράς, καθώς αυξάνονται οι ανάγκες παραγωγής.

Διαθέσιμο σε πλάτη 76, 137, και 198 cm, διαθέτει ζώνη προθέρμανσης υψηλής ισχύος που ανεβάζει τη θερμοκρασία του μελανιού πάνω από 149°C μέσα στα πρώτα εκατοστά της διαδρομής του ιμάντα, μεγιστοποιώντας την απόσταση και τον χρόνο παραμονής για βέλτιστο στέγνωμα κάθε τύπου μελανιού ή κόλλας, επιτρέποντας αυξημένες ταχύτητες ιμάντα και υψηλότερη παραγωγικότητα.

Το μοντέλο LittleRed X3-D-30 διαθέτει ιμάντα πλάτους 76,2 cm και τρεις μονάδες υπερύθρων πλάτους 61 cm (συνολική ισχύς 8.900W @ 240V) και μπορεί να στεγνώσει:

- 360+ τεμάχια/ώρα τυπωμένα με μελάνια plastisol

- 185+ τεμάχια/ώρα τυπωμένα με μελάνια νερού ή ξεβαφής

- 51+ τεμάχια/ώρα τυπωμένα με ψηφιακό λευκό μελάνι inkjet, με χρόνο παραμονής 3 λεπτών.

Το μοντέλο LittleRed X3-D-54 (πλάτος 137 cm) στεγνώνει:

- 720+ τεμάχια/ώρα τυπωμένα με μελάνια plastisol

- 370+ τεμάχια/ώρα τυπωμένα με μελάνια νερού ή ξεβαφής

- 103+ τεμάχια/ώρα τυπωμένα με ψηφιακό λευκό μελάνι inkjet ή προθερμασμένα για DTG, με χρόνο παραμονής 3 λεπτών.

Το μοντέλο LittleRed X3-D-78 (πλάτος 198 cm) στεγνώνει:

- 1.080+ τεμάχια/ώρα τυπωμένα με μελάνια plastisol

- 555+ τεμάχια/ώρα τυπωμένα με μελάνια νερού ή ξεβαφής

- 155+ τεμάχια/ώρα τυπωμένα με ψηφιακό λευκό μελάνι inkjet ή προθερμασμένα για DTG, με χρόνο παραμονής 3 λεπτών.

Τα μοντέλα X3-D-30 και X3-D-54 έχουν συνολικό μήκος ιμάντα 224 cm, ενώ το μοντέλο X3-D-78 έχει συνολικό μήκος 260 cm. Ο θάλαμος στεγνώματος και για τα τρία μοντέλα έχει μήκος 104 cm και διαθέτει ισχυρό, στοχευμένο σύστημα απαγωγής, για γρήγορη απομάκρυνση υγρασίας και αερομεταφερόμενων ρύπων, ενώ παράλληλα ψύχει το περίβλημα και τα χειριστήρια.

Με την προσθήκη δεύτερου θαλάμου X3, τα μοντέλα LR-X3D-30-2 και LR-X3D-54-2 μπορούν να διαχειριστούν υψηλότερη παραγωγή.

Προαιρετικός εξοπλισμός:

- Πρόσθετοι θάλαμοι στεγνώματος και επεκτάσεις ιμάντα μεταφοράς

- Λειτουργία με τάσεις 240V και 400V

- Τροχοί με φρένο για εύκολη μετακίνηση

- Λειτουργία χαμηλής ταχύτητας

.png)